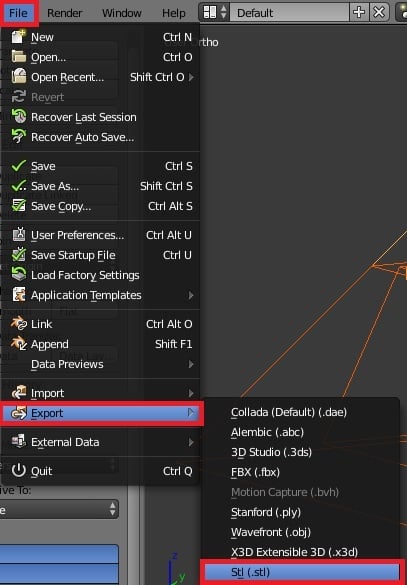

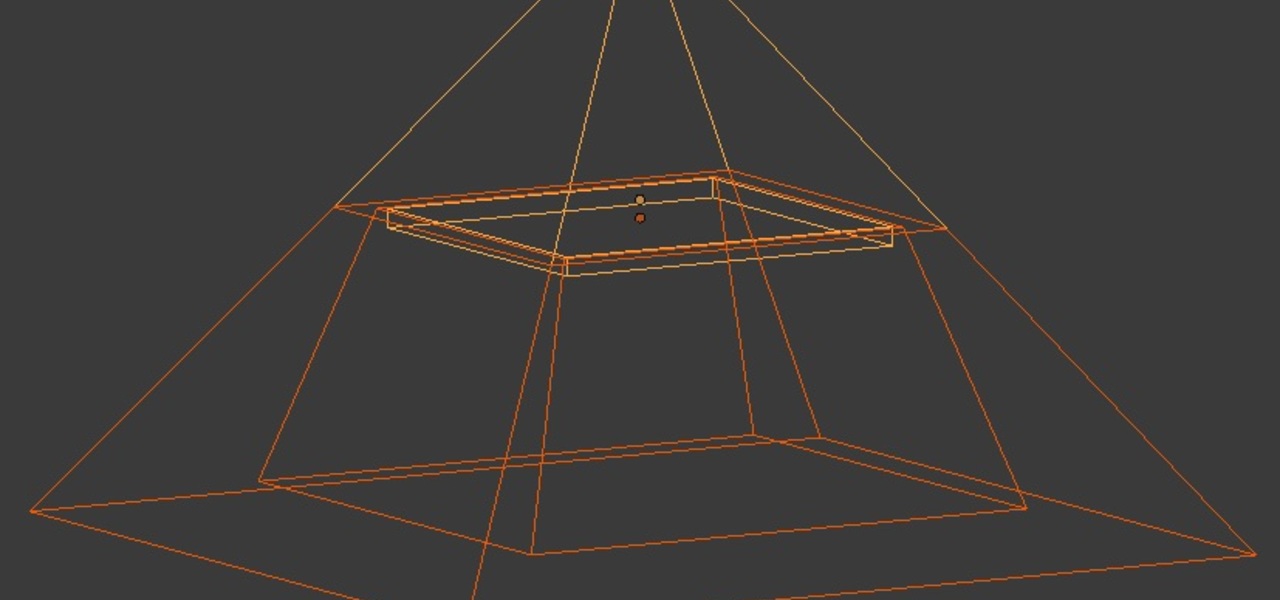

You need a base layer, or raft as it’s often called and supports going to the hands. For example printing a human from the feet up. Also the first player not having enough contact to support the model. The biggest failure point is supports, not having enough or in the wrong place. I always have to go in and inflate that area a bit to get it to print. For example the ear lobes on a human head model. For resin I’m using Chitu box but I’m looking for a better slicer.īiggest problem I’ve run across is an area not being thick enough for the resolution. I’m using Autodesk mesh mixer and Zbrush for some clean up work on models and for FDM printing I’m using Simplify 3d for Slicing. i.e No intersection polygons, welded edges, watertight etc. FDM models need to be put together better. First question is what type of printer are you using? Resin or FDM? Resin slicing will be more forgiving since it’s just outputting a cross section of the model. I have two FDM printers and two resin printers.

I haven’t used the 3d printing add on yet. I’ve set up supports in Blender for a resin printed model.

0 kommentar(er)

0 kommentar(er)